Current location:Home > Product Center > Metal Materials Series > Architectural Color Plates

0512-58775866

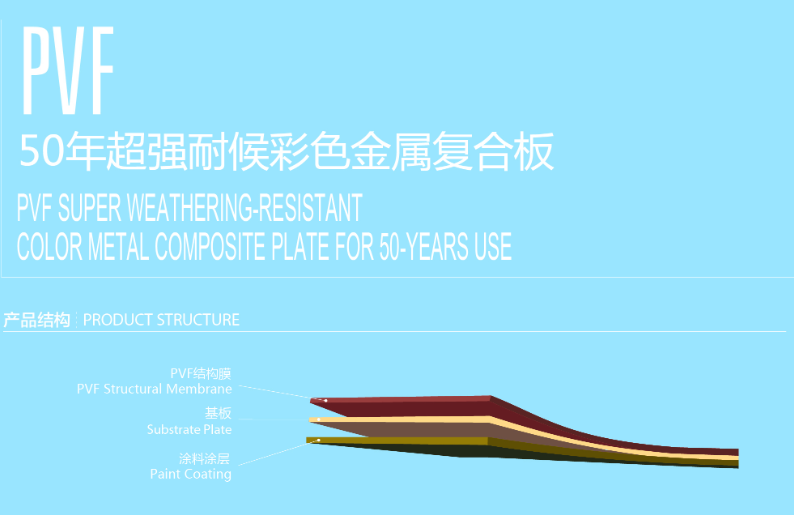

PVF series product main use of technology: DuPont Tedlar polyvinyl fluoride - DuPont Special Energy (PVF)

DuPont 50 years highest international design standard

Selection of color plates for national key projects

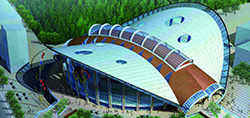

Application industry: national key projects, mainly including stadiums, high-speed rail stations, exhibition halls and other public buildings, such as the Bird's Nest, the Water Cube, Beijing South Railway Station, the National Grand Theater and so on.

Industry characteristics: public buildings concern a lot of people and are close to each other, therefore, aesthetics and durability are the primary considerations of color-coated steel plate, and the requirements for the coating to resist discoloration and chalking as well as the surface integrity and finesse are quite high.

Industry building (standard): the base material adopts AZ150 aluminum-zinc-plated sheet, Z275 galvanized sheet or aluminum-manganese-magnesium alloy sheet; the front coating generally adopts PVDF fluorocarbon, reinforced polyester or HDP high-weathering, and is mostly light-colored; the coating structure is mostly two-coating and two-drying based, and the thickness of the front coating is 25μm.

Jiabang product standard: PVF + standard galvanized sheet (PVF 50 years design standard). Environmental colors can be designed, and all technical indexes are much higher than PVDF standard.

Boiler supporting color plate selection program

Application industry: Boiler supporting color plate mainly includes boiler outer packaging, boiler insulation and outer protection board.

Characteristics of the industry: the temperature difference between hot and cold of the boiler is relatively large, and it is easy to form condensate, which requires that the color plate coating as the outer packaging and the outer sheathing board has the performance of high temperature resistance and temperature difference resistance.

Industry building (standard): According to the characteristics of the boiler industry, it is recommended to use PVDF fluorocarbon, reinforced polyester coated color plate, but taking into account the cost and cost, at present the boiler industry is still mainly used in the PE polyester coated color plate, the color is mainly silver grey and white, the zinc layer of the substrate on both sides of the 80 grams/square meter, the thickness of the coating is not less than 20 μm.

Jiabang product standard: PVF + standard galvanized sheet. Weather and temperature resistant, with the best barrier properties. Or use PPM and UVP series with second best barrier property.

Pipe insulation anti-corrosion color plate selection program

Application industry: heat, oil, natural gas, chemical products transmission pipeline insulation, anticorrosion engineering, etc..

Industry characteristics: As the color coated sheet not only has excellent oxidation and corrosion resistance, but also more colorful, the traditional galvanized sheet pipeline anti-corrosion has been gradually replaced by the color plate.

Industry construction (standard): In order to reduce the cost and cost, it is recommended to use ordinary PE polyester color plate with zinc layer not less than 80g/sqm and front coating thickness not less than 20μm. For oil and natural gas transmission pipelines in the field, considering the special environment in which the pipelines are located, it is recommended to use PVDF fluorocarbon, reinforced polyester or HDP high weather-resistant color plate.

Jiabang product standard: PVF + standard galvanized sheet. UVP series is recommended for general projects, which can design environmental color and realize double-sided lamination with good barrier property.

Chemical anti-corrosion engineering color plate selection program

Application industry: chemical workshop, chemical tank insulation and anti-corrosion projects.

Industry characteristics: chemical products have volatile characteristics, easy to produce acidic or alkaline and other corrosive volatile substances, in contact with water is easy to form dew attached to the surface of the color plate, the color plate coating corrosion, and may be further corrosion to the zinc layer or even steel plate.

Industry construction (standard): considering the special nature of the chemical industry's anti-corrosion requirements, it is recommended to use PVDF fluorocarbon color plate, reinforced polyester color plate or HDP high weathering color plate, with Z275 galvanized plate or AZ150 aluminum-zinc-plated substrate, and the thickness of the front coating is 20-25 μm; of course, the standard can also be lowered appropriately according to the specific cost and requirements of the project.

Jiabang product standard: PVF + standard galvanized sheet. Environmental colors can be designed, and all technical indexes are much higher than PVDF.

Food and drug workshop color plate selection program

Application industry: food, drug purification production workshop, hospitals and other areas with strict requirements for antimicrobial.

Industry characteristics: food, drug industry belongs to the national special supervision industry, the hygiene environment of the production workshop requirements are extremely strict, unqualified hygiene environment will directly affect the safety of food and drugs.

Industry building (standard): antibacterial color plate coating due to the use of a special enamel series of antibacterial agents, with non-toxic and semi-permanent antibacterial effect and far-infrared radiation effect. For coliform bacteria and yellow staphylococcus can produce more than 99% antibacterial rate, in the pharmaceutical, food processing and other antibacterial requirements of the more stringent areas are widely used. At the same time, easy-clean boards are also widely used in the food and pharmaceutical industries because of the good hydrophilic properties of the coating and the easy cleaning of the board surface. Therefore, it is recommended to use antimicrobial color plates or easy-to-clean color plates for food and pharmaceutical industries. For the selection of substrate, it is recommended that the zinc layer on both sides should not be less than 80g/m2 and the thickness of the coating on the front side should not be less than 20μm.

Jiabang product standard: PVF + standard galvanized sheet with the lowest surface polarity, the best barrier, the best pollution cleaning resistance (quality far better than antibacterial and cleaning coating, aircraft interior standard). Ordinary project cost problems, you can consider UVP series of self-cleaning products, its surface has self-cleaning standards and good barrier, you can also consider PPM corrosion and weathering resistant metal composite plate materials.

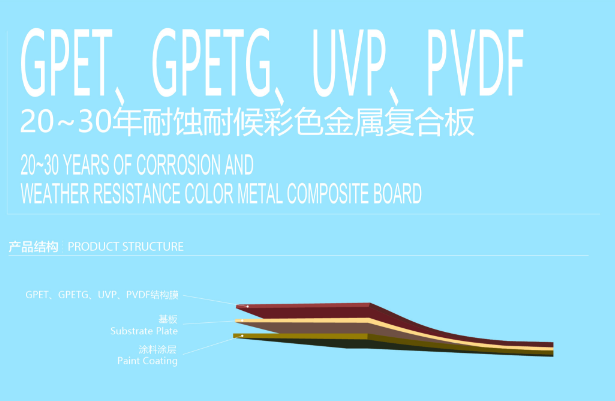

GPET, GPETG, UVP, PVDF series of products on the surface of the modified resin treatment material has a strong anti-ultraviolet function, to protect the color of the inner layer of the material durability and aging resistance.

20~30 years weathering and corrosion resistance design standard: can replace the surface fluorocarbon coating treatment of metal materials.

Good processing and molding performance, can meet different personalized processing needs.

Steel plant / power plant color plate selection program

Application industries: non-ferrous metal smelters, steel mills, power plants, etc.

Industry characteristics: non-ferrous metal smelting plant (copper, zinc, aluminum, lead, etc.) is the most challenging color plate life, steel mills, power plants, etc. will also produce corrosive media, the color plate corrosion resistance requirements are high.

Industry building (standard): In view of the specificity of metallurgical power industry, it is generally recommended to choose PVDF fluorocarbon color plate, reinforced polyester color plate or HDP high weather-resistant color plate. The zinc layer on both sides of the substrate is recommended to be not less than 120g/m2, and the thickness of the coating on the front side is not less than 25μm.

Jiabang product standard: UV resistant UVP weathering grade color composite panel or PPM corrosion resistant weathering metal composite panel and PVF 50 years super weathering color panel instead of PE polyester coating (equivalent to the PVDF coating standard).UVP series can be designed for environmental color and double-sided lamination standard.

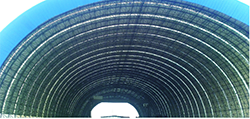

Gable roof color plate selection scheme

Application industry: Gable roof, mainly used in stadiums, trade markets, exhibition halls, warehousing and logistics and other fields.

Industry characteristics: The arched roof is widely used in stadiums, trading markets, exhibition halls, warehousing and logistics due to its beamless and purlin-less construction structure, open space, large spanning capacity, low cost, low investment, short construction period, and economic benefits. Due to the construction structure without beams and purlins and large space span, the arched roof requires high strength of color plates.